“Well, you’re going to have to have to give us more money,” the 12 year old demanded, in a tone that would accept no excuses. So how, exactly does one get into a position where they are being mugged by a sixth grader?

For the past eight years, JCJ Architecture has teamed up with the Gideon Welles School of Glastonbury, CT, to participate in CANstruction . In this event, teams build large sculptures out of canned goods. After a brief display period, the structures are dismantled and the cans are donated to local food banks to feed those in need. JCJ has a strong student focus on the projects, and strives to educate about how budgets influence architectural design and make this partnership a true learning experience for the team.

CANstruction gives students the opportunity feed the hungry while exploring how budgets influence architectural design.

Over the course of six months, architects from JCJ led several classes to teach the sixth graders about the CANstruction design process and how that process relates to real world construction projects. This year, Meghan Carrier, Gideon Welles’ PACE teacher, challenged us to add a new class to the curriculum: “How does Budget influence the Design Process?.” All too often, designers are portrayed as creative geniuses divorced from any attachment to reality, bemoaning that their beautiful ideas can’t be supported by the evil budget. This was an opportunity to refute that myth, and show how, when properly used, the budget is actually an ally in the process.

Like any building project, our CANstruction must start from the big picture and then refine, refine, refine. Fortunately, the students do a simplified house design project in 5th grade, and so are already familiar with the basics of area measurement. And so we draw a parallel: just as we know from historical precedent, expert analysis, and personal experience that a certain building type might cost on average $250 per square foot, so too we can say that, on average, a can used in CANstruction will cost about $1.50. By dividing our budget by this value, we are able to estimate how many cans we have to build with, and thus, about how big our sculpture might be. We also explain how we sometimes do the inverse and multiply a square footage cost by a design’s area to create the estimated cost. This big picture estimating helps guide the initial design decisions.

At this point, we have calculated that we have about 1,000 cans, which sounds like a lot, but when efficiently stacked will only be a 30”x30”x48” block, which is evident by another simple math example. Not terribly impressive. The students are disappointed. Their aspirations for a monument to their creative genius are crushed. To help ease the pain, we introduce the Project Management Triangle, also known as the Triple Constraints: Time, Scope, and Cost. We explain how the three interact to determine the quality of a project: An increase in scope necessitates an increase in time or cost, a reduction in time demands a reduction of scope or increase of cost, etc. In our case, the time is fixed by the event schedule. The cost is fixed by the set School budget. And so the only place we have any give is in the scope of what we do – until a particularly brave student sees another alternative: holding us at verbal gunpoint.

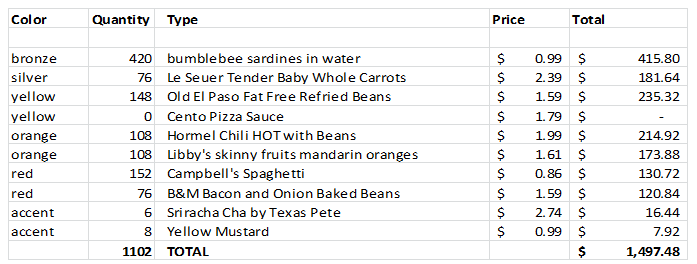

Sample estimated can budget for a CANsculpture.

But wait - there’s a peaceful way out of this!

Instead of jumping immediately to the conclusion that we need more money – an all too common response – let’s instead evaluate how we are using the resources that we have. We have the students brainstorm a few alternatives to get more mileage from our budget: we could use less expensive cans that match the properties we want (in this case color and size). We could hollow out the sculpture to cover more area. We could arrange discounts by reducing the number of kinds of cans and then buying in bulk. We explain to them that this is the true intent of Value Engineering and working with a budget. It’s not about blindly cutting line items to save money. It’s about using set parameters to help define resources, and then using those resources to the cleverest way we can to achieve the initial goal. We explain that their suggestions are among the most common and successful strategies used in building projects. And these strategies help turn a simple block into an award winning sculpture.

Article by Daniel Thornton, RA, CDT, LEED AP